For detailed information, other images and documents, please select individual articles from the following table.

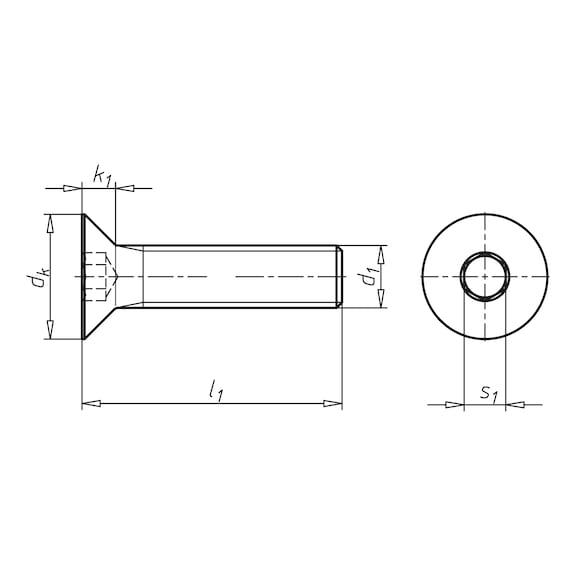

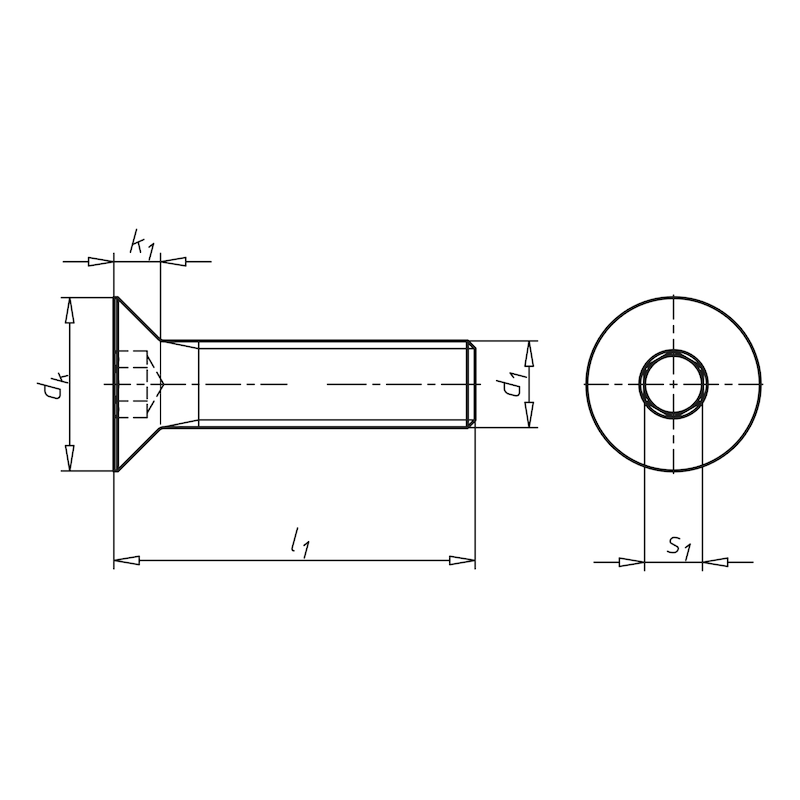

Countersunk screw with hexagon socket head ISO 10642, steel, strength class 8.8, zinc-nickel-plated, silver (ZNSHL)

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Fasteners with a zinc-plated chromium (VI)-free zinc-nickel silver coating (ZNSHL) are suitable for applications with a high risk of corrosion. The coating comprises a zinc-nickel alloy layer and a sealing coat (top coat with integrated lubricating particles).

Corrosion resistance:

- Diameter ≥ M2 – 360h*

- Diameter ≥ M4 – 600h*

- Diameter ≥ M10 – 720h*

- *No base metal corrosion at points without thread in salt spray mist testing according to DIN EN ISO 9227 NSS

Overview of advantages:

- Corrosion resistance of up to 720 hrs to base metal corrosion in accordance with DIN EN ISO 9227 NSS

- Chromium(VI)-free

- Adjusted friction coefficient range of 0.09 μ–0.14 μ due to top coat with integrated lubricating particles

- Thermal capacity up to 120°C

- Even coat distribution

- Functional and decorative

ISO 10642 replaces DIN 7991 | There is some limited similarity (some head heights and head diameters have been changed | nominal Ø M18, M22, M24 are omitted | Stainless steels removed | strength classes 10.9 and 12.9 added).

These screws can only be subjected to limited loads due to their head geometry, see DIN EN ISO 898-1

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!