Twist drill bit HSS DIN 1869 R2 SMART STEP

Twist drill bit HSS DIN 1869 R2 SMART STEP

DRL-TWST-MET-DIN1869-HSS-SMARTSTEP-D5,0

ZEBRA SMART STEP

Register now and access more than 125,000 products

The first extra-long twist drill bit with stepped drill bit tip geometry

Precise, circular holes without centre-punching

Up to 100 % faster than conventional extra-long HSS drill bits

Extremely comfortable drilling

- Eliminates pre-drilling despite the extra-long design, precise spot drilling

- Prevents the tool from running off-centre even during particularly deep drilling

- Significantly less effort required when drilling compared to conventional extra-long twist drill bits

- Simple drilling or enlarging of an existing drill hole

3-flat shank

- No spinning in the drill chuck: faster, more comfortable working

- Optimal power transmission

- Protects the drill chuck from damage

- Minimal effort required to loosen and tighten the drill chuck

Product packaging made from 100 % PCR (recycled plastic from household waste) and 100 % recyclable

Available exclusively from Würth

For blind holes, please note the extended drill tip (see dimension l3)!

Datasheets(X)

- Ideal for drilling thin-walled composite materials, e.g. in window construction (plastic profiles with steel core)

- High quality of drill holes and significantly longer service life compared to conventional wood boring bits.

- Perfect for cordless drill drivers as well as handheld and pillar drill and drill presses

- Universally suited for smooth as well as rounded and uneven surfaces

For optimum drilling progress and to avoid jamming, use “pecking cycles” for large drilling depths.

| |

Suitable for machine type | Drill, Cordless screwdrivers, Pedestal drilling machine |

Material to be processed | Steel, Cast iron, Non-ferrous metal, Wood, Hardwood |

Quality | ZEBRA-Premium |

Standard / drilling depth | DIN 1869 / 25xD |

Design | Overlong |

Diameter (Ø) | 5.0 mm |

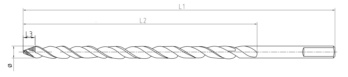

Length (l1) | 245 mm |

Chip flute length (l2) | 170 mm |

Drill tip length (l3) | 3.9 mm |

Shank style | 3-face shank |

Surface | Multiple refined |

Cutting material | HSS |

Service life (points system) | 3 of 4 points |

Drilling speed (point system) | 4 of 4 points |

Bore hole quality (point system) ( ) | 4 of 4 points |

Versatility (points system) | 3 of 4 points |

Drilling behaviour (point system) | 4 of 4 points |

Suitable for drill (points system) | 4 of 4 points |

Suitable for cordless drills (points system) | 4 of 4 points |

Suitable for upright drilling machine (points system) | 4 of 4 points |

Self-centring | Yes |

Suitable for tensile strength up to | 1000 N/mm² |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Alloyed tempering steels, Nitriding steels, Tool steels, High-speed steels, Cast iron, Ductile iron, Malleable cast iron, Aluminium, Aluminium alloys, Aluminium wrought alloys, Aluminium casting alloys (<10% silicon), Magnesium alloys, Copper, low-alloyed, Brass, short-chipping, Brass, long-chipping, Bronze, short-chipping, Bronze, long-chipping, Plastics, thermoset, Plastics, thermoplastic, Plastics, aramide-fibre reinforced, Plastics, glass/carbon-fibre-reinforced |

| Cutting parameters for twist drill bit HSS DIN 1869 R2 SMART STEP | ||||||||||||

| For dia. 4.0–6.0 | ||||||||||||

| Material designation | Tensile strength | From dia. 4.0 | From dia. 5.0 | From dia. 6.0 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| General structural steels | ≤ 850 N/mm² | 18 | 27 | 1433 | 2149 | 0,020 | 1146 | 1719 | 0,025 | 955 | 1433 | 0,027 |

| Unalloyed heat-treated steels | ≤ 850 N/mm² | 18 | 27 | 1433 | 2149 | 0,020 | 1146 | 1719 | 0,025 | 955 | 1433 | 0,027 |

| Low-alloy heat-treated steels | ≤ 850 N/mm² | 18 | 27 | 1433 | 2149 | 0,020 | 1146 | 1719 | 0,025 | 955 | 1433 | 0,027 |

| Unalloyed heat-treated steels | ≤ 1000 N/mm² | 15 | 23 | 1194 | 1831 | 0,018 | 955 | 1464 | 0,021 | 796 | 1221 | 0,025 |

| Low-alloy heat-treated steels | ≤ 1000 N/mm² | 15 | 23 | 1194 | 1831 | 0,018 | 955 | 1464 | 0,021 | 796 | 1221 | 0,025 |

| Alloyed heat-treated steels | ≤ 1000 N/mm² | 10 | 15 | 796 | 1194 | 0,018 | 636 | 955 | 0,021 | 531 | 796 | 0,025 |

| Nitriding steels | ≤ 1000 N/mm² | 10 | 15 | 796 | 1194 | 0,018 | 636 | 955 | 0,021 | 531 | 796 | 0,025 |

| Tool steels | ≤ 1000 N/mm² | 10 | 15 | 796 | 1194 | 0,018 | 636 | 955 | 0,021 | 531 | 796 | 0,025 |

| High-speed steels | ≤ 1000 N/mm² | 10 | 15 | 796 | 1194 | 0,018 | 636 | 955 | 0,021 | 531 | 796 | 0,025 |

| Cast iron | ≤ 350 HB | 15 | 23 | 1194 | 1831 | 0,018 | 955 | 1464 | 0,021 | 796 | 1221 | 0,025 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 15 | 23 | 1194 | 1831 | 0,018 | 955 | 1464 | 0,021 | 796 | 1221 | 0,025 |

| Aluminium | ≤ 600 N/mm² | 35 | 45 | 2786 | 3582 | 0,020 | 2229 | 2866 | 0,025 | 1857 | 2388 | 0,027 |

| Plastics, duroplastic | 15 | 23 | 1194 | 1831 | 0,020 | 955 | 1464 | 0,025 | 758 | 1162 | 0,027 | |

| Plastics, thermoplastic | 15 | 23 | 1194 | 1831 | 0,020 | 955 | 1464 | 0,025 | 758 | 1162 | 0,027 | |

| Softwood | 21 | 30 | 1672 | 2388 | 0,023 | 1338 | 1910 | 0,028 | 1114 | 1592 | 0,030 | |

| Hardwood | 18 | 27 | 1433 | 2149 | 0,022 | 1146 | 1719 | 0,027 | 955 | 1433 | 0,030 | |

| Legend | |

| vc = cutting speed [m/min] | |

| f = feed [mm/r] | |

| n = speed [rpm] | |

| The suggested cutting values are reference values and must be adapted to the respective conditions. | |

| For dia. 8.0–13.0 | ||||||||||||

| Material designation | Tensile strength | From dia. 8.0 | From dia. 10.0 | From dia. 13.0 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| General structural steels | ≤ 850 N/mm² | 18 | 27 | 716 | 1074 | 0,03 | 573 | 859 | 0,035 | 440 | 661 | 0,038 |

| Unalloyed heat-treated steels | ≤ 850 N/mm² | 18 | 27 | 716 | 1074 | 0,03 | 573 | 859 | 0,035 | 440 | 661 | 0,038 |

| Low-alloy heat-treated steels | ≤ 850 N/mm² | 18 | 27 | 716 | 1074 | 0,03 | 573 | 859 | 0,035 | 440 | 661 | 0,038 |

| Unalloyed heat-treated steels | ≤ 1000 N/mm² | 15 | 23 | 597 | 915 | 0,028 | 477 | 732 | 0,031 | 367 | 563 | 0,035 |

| Low-alloy heat-treated steels | ≤ 1000 N/mm² | 15 | 23 | 597 | 915 | 0,028 | 477 | 732 | 0,031 | 367 | 563 | 0,035 |

| Alloyed heat-treated steels | ≤ 1000 N/mm² | 10 | 15 | 398 | 597 | 0,028 | 318 | 477 | 0,031 | 245 | 367 | 0,035 |

| Nitriding steels | ≤ 1000 N/mm² | 10 | 15 | 398 | 597 | 0,028 | 318 | 477 | 0,031 | 245 | 367 | 0,035 |

| Tool steels | ≤ 1000 N/mm² | 10 | 15 | 398 | 597 | 0,028 | 318 | 477 | 0,031 | 245 | 367 | 0,035 |

| High-speed steels | ≤ 1000 N/mm² | 10 | 15 | 398 | 597 | 0,028 | 318 | 477 | 0,031 | 245 | 367 | 0,035 |

| Cast iron | ≤ 350 HB | 15 | 23 | 597 | 915 | 0,028 | 477 | 732 | 0,031 | 367 | 563 | 0,035 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 15 | 23 | 597 | 915 | 0,028 | 477 | 732 | 0,031 | 367 | 563 | 0,035 |

| Aluminium | ≤ 600 N/mm² | 35 | 45 | 1393 | 1791 | 0,03 | 1114 | 1433 | 0,035 | 857 | 1102 | 0,038 |

| Plastics, duroplastic | 15 | 23 | 597 | 915 | 0,03 | 477 | 732 | 0,035 | 367 | 563 | 0,038 | |

| Plastics, thermoplastic | 15 | 23 | 597 | 915 | 0,03 | 477 | 732 | 0,035 | 367 | 563 | 0,038 | |

| Softwood | 21 | 30 | 836 | 1194 | 0,033 | 668 | 955 | 0,038 | 514 | 734 | 0,041 | |

| Hardwood | 18 | 27 | 716 | 1074 | 0,032 | 573 | 859 | 0,036 | 440 | 661 | 0,038 | |