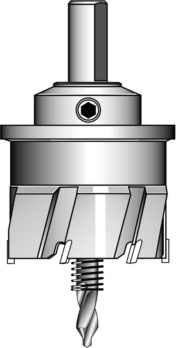

MBS HW cylinder saw

MBS carbide cylinder saw

SAW-CYL-TC-MBS-D35MM

ZEBRA

Register now and access more than 125,000 products

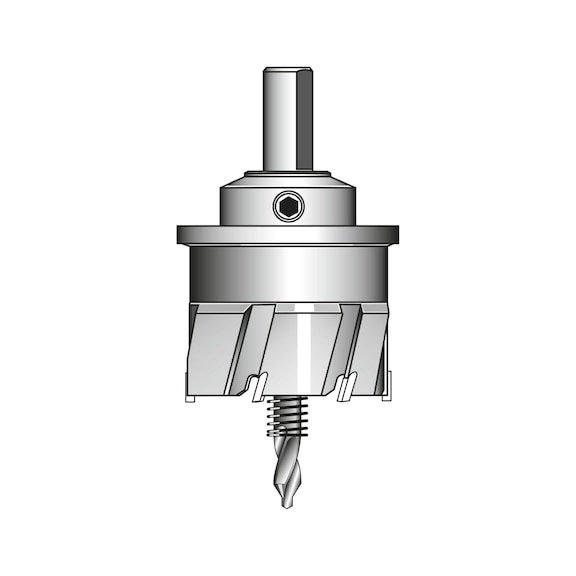

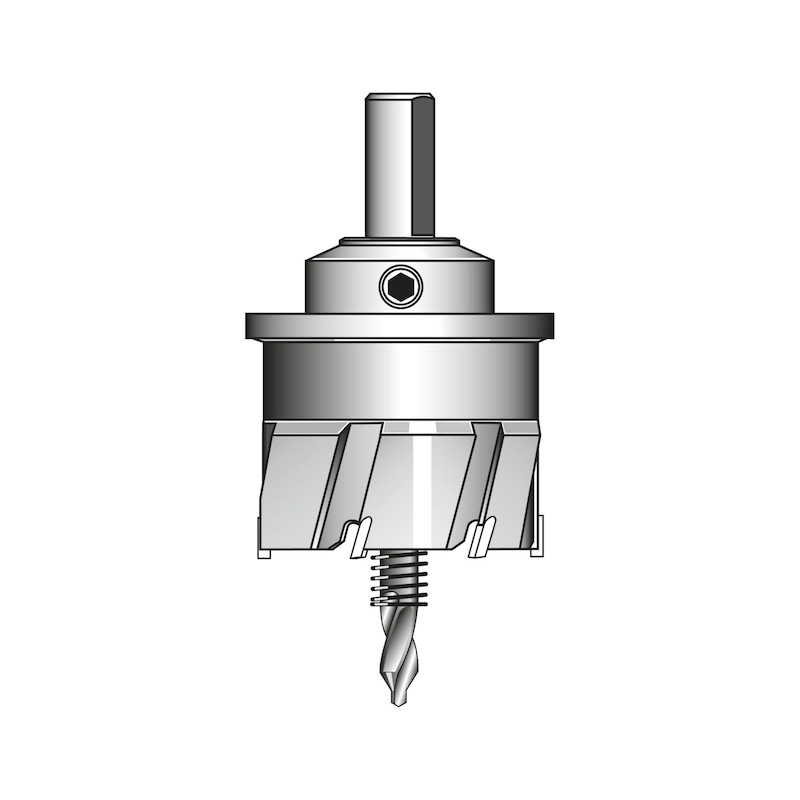

Even CNC cut with cutting geometry specifically aligned to reduce cutting pressure

Precise, clean drill hole with low tolerances

Offset, optimised centre drill (GS-protected system)

- Eliminates the need for laborious centre punching, as the drill can be centred without drifting off course

- Reduced drilling force and over 50% reduction in drilling time coupled with lower power consumption (depending on the hand-held drill used)

Precise, optimally embedded seating of the cemented carbide teeth via a unique, fully automatic soldering process

High cutting performance with a long service life

Ejector spring

- Protects shock-sensitive carbide teeth after pre-drilling when the drill bit enters the medium

- Automatically ejects the drilled section ("drill core") when drilling is complete: Caution: Ejection spring can be used with materials up to 8 mm thick. With thicker materials, the spring must be removed. Otherwise, the cutting depth will be limited (spring is compressed).

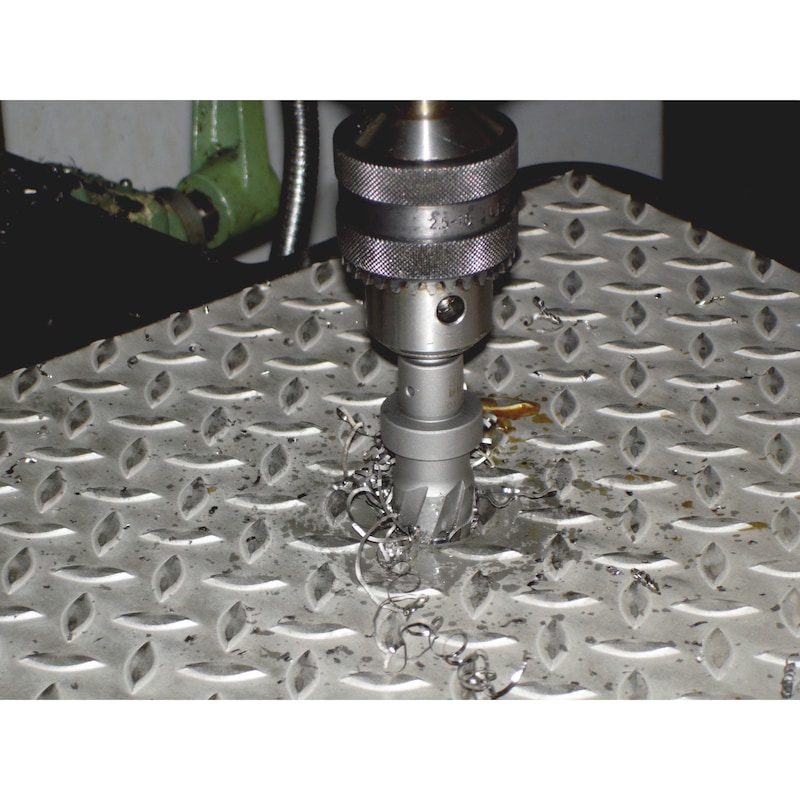

Solid basic body with offset chip grooves

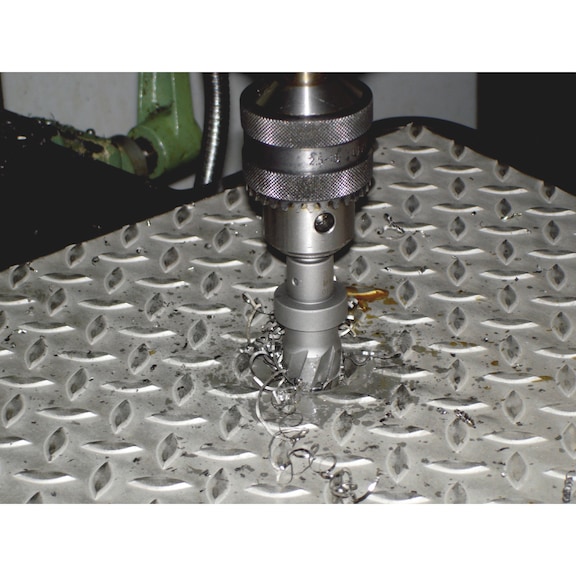

Optimum removal of chips, even with thicker materials: Caution: We nevertheless recommend "ventilating" the hole saw, i.e. stopping it and removing the chips, when working with material depths of 6 mm and greater. Work may then continue.

Separately tempered shank from∅ 32 mm

Compensation for the increasing ∅ torsional forces and torques associated with increasing diameters

Ensure that the cylinder saw is secure in the drill chuck. Avoid using the cylinder saw at an angle. Wear appropriate protective clothing, e.g. safety glasses, gloves etc. when working.

Datasheets(X)

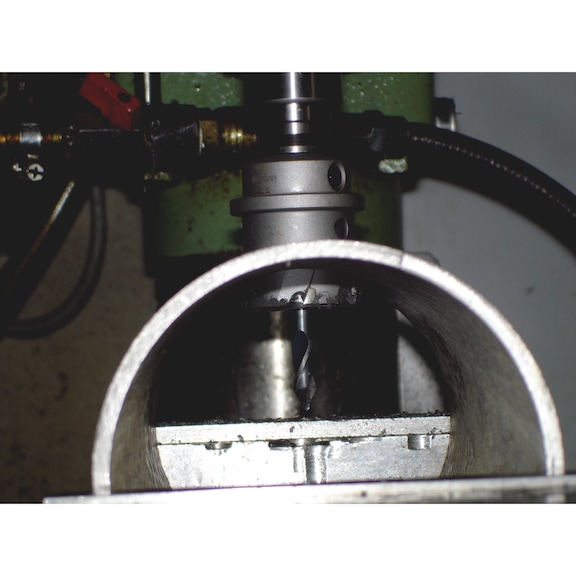

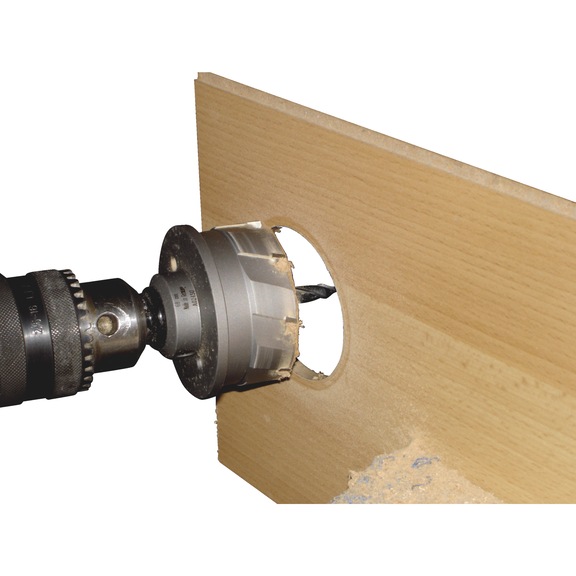

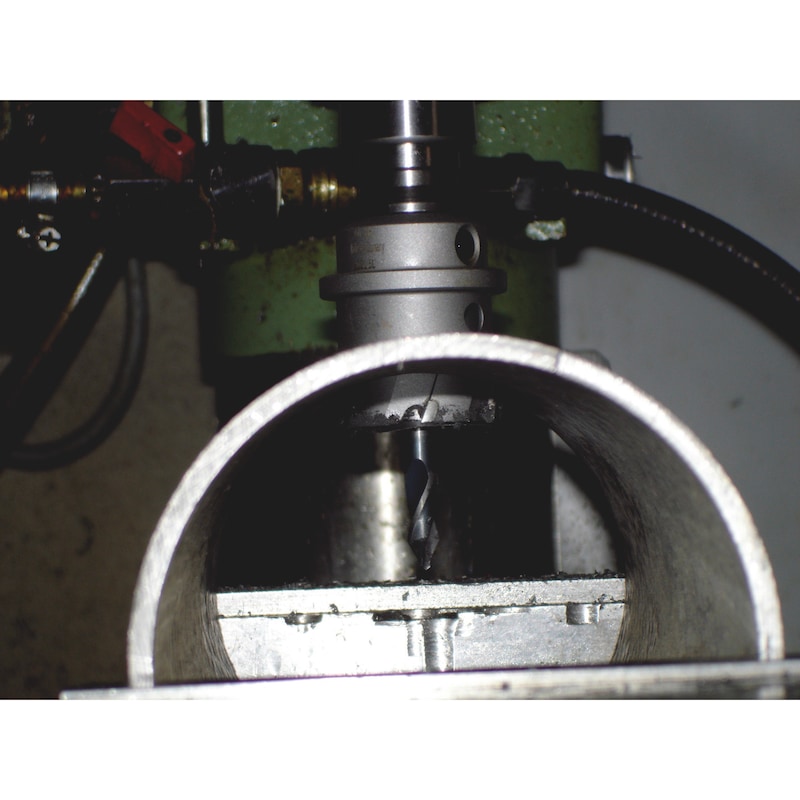

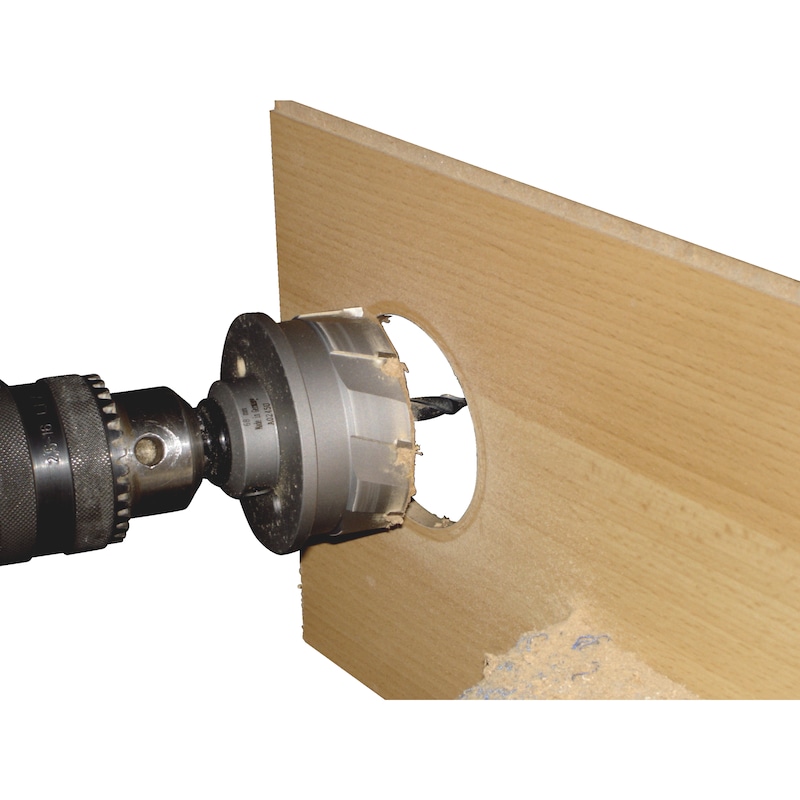

For use with upright and hand-held drills in tool steels, construction steels, non-ferrous metals, non-rusting metals (e.g. A2 and A4), plastics, solid wood, laminate, aerated concrete and plasterboard. Suitable for cutting pipes and curved or profiled surfaces (also for overlapping holes).

- Hand drill up to 6 mm material thickness and max. 30 mm saw diameter.

- Drill press up to max. 20 mm material thickness and > 30 mm saw diameter.

- Recommendation: MK-2 drive arbor for saws of 64 mm diameter, though can be used for saws from 32 mm diameter.

- Recommended speeds must be observed.

- Ensure that the saw is sufficiently cooled/well lubricated.

- For further information on use, refer to the operating instructions.

| |

Diameter (Ø) | 35 mm |

Width across flats | 3/4 inch |

Cutting depth | 20 mm |

Drive type | Triangle |