HSS AlTiN SMART STEP stepped twist drill bit

Stepped twist drill bit HSS AlTiN SMART STEP

DRL-STEP-SMARTSTEP-ALTIN-(D4-12MM)

ZEBRA SMART STEP

Register now and access more than 125,000 products

Innovative geometry with three chip surfaces between the individual step transitions

- Up to 3x longer service life compared to all other coated stepped drill bits

- Significantly faster drilling compared to all other coated stepped drill bits

- Minimal effort required

- Completely smooth, perfectly controlled drilling process

- Greatly reduced formation of burrs

SMART STEP technology

- Up to 3x faster drilling compared to conventional stepped drill bits

- Precision drilling without centring or centre-punching

- No warping of sheet metal

- Simple drilling or enlarging of an existing drill hole

- No rattling or catching in the material

- Precise, circular drilling without tearing or splintering

Deep ground spiral groove

Excellent chip removal

AlTiN multilayer wear protection coating

- Extremely high temperature resistance of up to 1,150°C

- Very high coating hardness of 3,200 HV

- Multilayer structure for optimal chip removal and improved cutting properties (prevents material becoming welded)

3-flat shank

- No spinning in the drill chuck: faster, more comfortable working

- Optimal power transmission

- Protects the drill chuck from damage

- Little effort required to open and close the drill chuck

Sustainable product packaging made of 100 % PCR (recycled plastic from household waste), 100 % recyclable and Cradle to Cradle Certified® Bronze

Available exclusively from Wurth

- Cooling not absolutely necessary, but significantly extends the service life

- Observe the rotation speed table

- Do not push during boring. The stepped drill bit automatically retracts into the sheet metal.

Datasheets(X)

- The ideal tool for machining sheet metal.

- Centring, spot drilling, boring and deburring of sheet metal, tubes and profiles in one operation, for use on both hand drills and stationary equipment.

- Ideal for use in electrical trade, plumbing and heating systems, automotive workshops, mechanical engineering, switch cabinet manufacturing or container and equipment engineering.

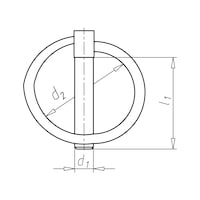

Min./max. drill diameter | 4-12 mm |

Shank diameter | 6 mm |

Shaft length | 24 mm |

Length | 67.5 mm |

Shank style | 3-face shank |

Surface | AlTiN |

Type description | HSS AlCrN SMART STEP |

Material to be processed | Steel |

| Art. no. | Number of steps | Diameter of the drilling area [mm] |

| 0694451412 | 9 | 4.0/5.0/6.0/7.0/8.0/9.0/10.0/11.0/12.0 |

| 0694451420 | 9 | 4.0/6.0/8.0/10.0/12.0/14.0/16.0/18.0/20.0 |

| 0694451630 | 13 | 6.0/8.0/10.0/12.0/14.0/16.0/18.0/20.0/22.0/24.0/26.0/28.0/30.0 |

| 0694451639 | 12 | 6.0/9.0/12.0/15.0/18.0/21.0/24.0/27.0/30.0/33.0/36.0/39.0 |

| 0694451640 | 16 | 6.5/8.5/10.5/12.5/14.5/16.5/18.5/20.5/23.5/25.5/28.0/30.5/32.5/35.5/38.5/40.5 |

| 0694451637 | 12 | 6.0/9.0/12.5 (PG7)/15.2 (PG9)/18.6 (PG11)/20.4 (PG13.5)/22.5 (PG16)/26.0/28.3 (PG21)/30.5/34.0/37.0 (PG29) |

| 0694451628 | 8 | 6.0/9.0/11.4 (PG7)/14.0 (PG9)/17.25 (PG11)/19.0 (PG13.5)/21.25 (PG16)/26.75 (PG21) |

| 0694451538 | 11 | 5.3/7.0/9.0/10.5/14.5/18.5/23.5/27.0/30.5/34.5/38.5 |

| 0694451638 | 12 | 6.0/9.0/13.0/16.0/19.0/21.0/23.0/26.0/29.0/32.0/35.0/38.0 |

| Key |

| vc = cutting speed [m/min] |

| n = rotation speed [rpm] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!