HPC end mill with corner radius Speedcut 4.0-Universal, long, optional, four cutting edges, uneven angle of twist gradient

Mill. cutter SC4.0 Uni DIN6527L type N Twind ER HA

ENDMIL-SP-4.0-DIN6527L-UV-TD-HA-D6X0,5

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 8547 |

Material to be processed | Steel |

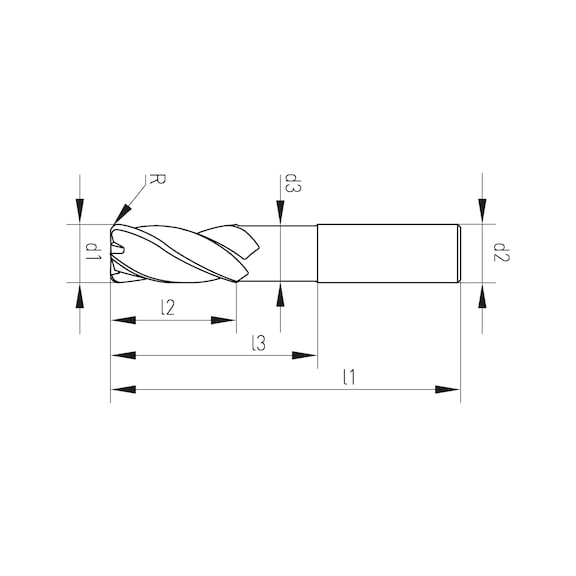

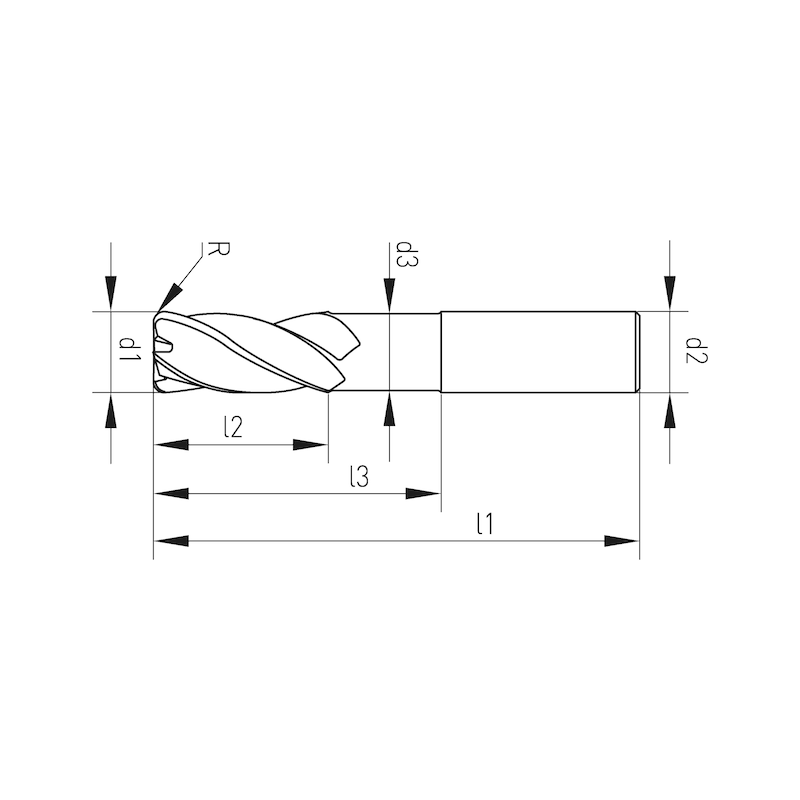

Diameter (d1) | 6 mm |

Shank diameter (d2) | 6 mm |

Clearance diameter (d3) | 5.5 mm |

Standards | DIN 6527 |

Construction length | Long |

Shank style | Cylindrical DIN 6535-HA |

Cutting material | SC |

Surface | TWINDUR |

Coolant supply | External |

Twist angle | 35-38° |

Corner radius (R) | 0.5 mm |

Length (l1) | 57 mm |

Cutting edge length (l2) | 13 mm |

Clearance length (l3) | 21 mm |

Number of cutting edges (Z) | 4 PCS |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | General structural steels |