ASSY® 4 COMBI T transportation anchor screw Steel zinc plated partial thread hexagon head

ASSY 4 COMBI steel zn for transport anchor RW

SCR-WO-HEX-RW40-(A3K)-12X120/100

ASSY 4 COMBI T

Register now and access more than 125,000 products

Ideal power transmission thanks to RW drive

- More power due to larger contact area at the bit

- More stability, one-handed working, precise positioning due to the tight-fit recess and perfect fit of the bit

- Fewer bit changes, one bit for many screw diameters

- Compatibility with previous AW drive

Flexible assembly with high power transmission and precise fit in metal connections

- Combination of hexagon head and RW drive with reinforced shaft attachment

No over-tightening or stripping and high feed

- Higher power transmission in hardwoods due to reinforced, asymmetrical thread flank geometry of the coarse thread

- Better anchoring thanks to higher thread flanks

Smooth thread start ensures optimised recessing and biting of the screw

- Low gap effect due to displacement effect of the dome-shaped milling elements in the tip

- Friction-reduced thread rotation allows reduction of the screw-in force to be applied

High strength values and ductility

- Adjusted heat treatment guarantees high strength values and high ductility

Please observe the available expert reports, application instructions and load tables during planning and application. These are available at www.wuerth.de/assy.

ETA-11/0190 approved

- The load capacity of the transport anchor in conjunction with the ASSY 4 COMBINATION T transportation anchor screw must be checked in accordance with the test report/expert report before each transport operation and must be verified separately.

- The specifications of ETA 11/0190 and the expert reports on the use of the screw as a transport screw must be observed

Datasheets(X)

For the transport of wooden elements, such as walls or ceilings made of coniferous timber, laminated timber, timber veneer or board plywood

Application examples:

- Axial force in panel surface or narrow edge of panel

- Oblique force in panel surface or narrow edge of panel

- Oblique force in panel surface with precise milled recess (t x d, 70 x 30 mm)

- Wood construction, structural wood construction, board plywood constructions, packaging

- For safety reasons, the screws must only be used once. The whole component should also be connected with at least two wood screws. Ensure that the screws are not screwed into shrinkage cracks or similar. For statically indeterminate suspensions with more than three strands, the anchors must be appropriately dimensioned so that two anchor points can hold the entire load. The loads on the anchor points must be calculated according to the triangle of forces. For the attachment of more than 2 anchor points, statically determined suspensions, suitable measures must be ensured, e.g. spreader bar, for an even load distribution across all strands. Please refer to the available expert reports and load tables

- The thread of the screw must be fully anchored in the wooden surface without obstructing the component

- When screwing into the narrow edges of plywood boards, screw into the middle of a board layer. A transverse support must also be attached perpendicular to the panel surface around the screw fixings with ASSY plus VG full-thread screws

- When transport loads are applied, the transportation forces exerted on the transport anchor system must be taken into consideration in the form of vibration coefficients

- ASSY screws are approved for quasi-static loads

- For optimum use of the screw, the right-size RW bit or hexagon socket wrench must be used

| |

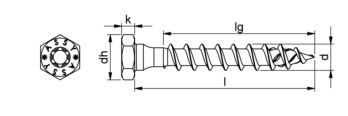

Nominal diameter (d) | 12 mm |

Length (l) | 120 mm |

Head type | Hexagon head |

Head height (k) | 5.5 mm |

External drive | WS17 |

Internal drive | RW40 |

Thread type | Wood screw thread |

Thread design | Full thread |

Thread form | Coarse thread |

Thread length (lg) | 100 mm |

Material | Hardened steel |

Surface | Zinc plated |

Suitable for use in the following materials | Board ply wood (BSP), Hardwood, LVL |

Area of application | Element construction, Timber panel construction, Structural woodwork, Metal wood connections |

Core diameter | 7.2 mm |

Shape of tip | Tip with hilltop milling cutter |

Angle of the tip | 34 Degree |

Max. screw-in angle | 90 Degree |

Min. screw-in angle | 0 Degree |

RoHS-compliant | Yes |

Approval | ETA-11/0190 |